In the fiercely competitive market for hygiene essentials, keeping production costs under control is essential. By implementing some strategic measures, you can drastically lower your expenses without neglecting product quality. A key initiative is to thoroughly analyze your current production system. Identify areas where efficiencies can be made, such as streamlining tasks and eliminating waste.

- Furthermore, consider bargaining with your providers to obtain more favorable pricing on raw components.

- Consider alternative materials that deliver comparable quality at a diminished cost.

- Bear in mind that investing in energy-efficient equipment and utilizing sustainable practices can both reduce your production costs and strengthen your brand's image.

Premium Wet Wipe Liquid Supplier: Low Lowest Order Amounts

Searching for a reliable wet wipe liquid supplier with flexible ordering options? Look no further! We specialize in providing premium quality wet wipe liquids at competitive prices, with low minimum order quantities to suit your needs. Whether you're a small business or a large corporation, we can cater/meet/fulfill your requirements with our wide range of formulas and scents. Our team is committed to delivering exceptional customer service and ensuring your complete satisfaction.

- Benefit 1

- Feature 2

- Benefit 3

Contact us today to discuss your wet wipe liquid needs and receive a personalized quote. We're confident that we can be your go-to supplier for all your wet wipe liquid requirements.

Eco-Friendly Alternatives: Plant-Based Preservatives for Wipes

In our quest for a eco-conscious future, the packaging industry is continuously seeking creative solutions to reduce its environmental impact. One such area of focus is implementing plant-based preservatives for wipes. Traditional preservatives often contain chemicals that can be harmful to both human health and the environment. Plant-derived alternatives, conversely, offer a healthier option while still providing effective protection against microbial growth. These organic preservatives are sourced from plants like rosemary, thyme, and peppermint, known for their inherent germ-fighting properties. The integration of plant-based preservatives in wipes is a leap towards a more sustainable future.

Cutting-Edge Wet Wipe Formulation Expertise

Navigating the complexities of wet wipe formulation can be demanding. With stringent regulations and evolving consumer expectations, ensuring your product is both performant and compliant is paramount. That's where our experts of skilled formulators come in. We offer comprehensive consultation services tailored to meet your specific needs, from initial concept development through final product launch. Our extensive knowledge of ingredients, processing techniques, and industry best practices allows us to design custom formulations that deliver exceptional efficacy. Whether you're seeking a innovative solution or looking to optimize an existing product, our team is here to guide you every step of the way.

- Advantage 1

- Benefit 2

- Benefit 3

State-of-the-Art Wet Wipe Manufacturing Expertise

Our company boasts a vast knowledge base in wet wipe manufacturing. We leverage advanced technologies to create high-quality wipes that meet the stringent requirements of diverse industries. From formulation development to manufacturing, our team of experts is committed to delivering exceptional outcomes. We are constantly exploring novel solutions to enhance our wet wipe manufacturing processes, ensuring we remain at the pinnacle of this dynamic field.

Maximize Profitability with Efficient Wet Wipe Production Strategies

In the fiercely competitive wet wipe market, boosting profitability requires a keen focus on efficiency. By implementing strategic production strategies, manufacturers can reduce costs and maximize output without sacrificing quality. A key element is the website adoption of automated manufacturing processes which streamline production lines. Furthermore, utilizing data analytics can provide valuable data to recognize areas for enhancement, leading to significant cost savings.

- Evaluate innovative materials to lower production costs.

- Allocate in sustainable manufacturing practices to cut operational expenses.

- Adopt a robust quality control system to prevent waste and rework.

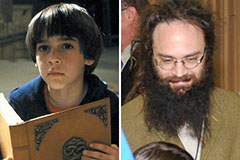

Barret Oliver Then & Now!

Barret Oliver Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now!